Masonry water-repellent PRO JET

The process involves the saturation of a select course of brickwork, or an equivalent area of blockwork or stone with PROJET under low pressure injection, and subsequent replastering. Replastering is necessary to retain salts in the body of the wall to prevent damage to subsequent redecoration.

PROJET develops its water-repellent properties by reaction with moisture contained in the treated wall.

Suitable for walls of brickwork, blockwork or natural stone (excluding flint) in solid walls with conventional cavity network.

After treatment, a wall previously affected by rising damp should normally dry out in 6 to 18 months, provided normal heating is used during the winter season and depending on the wall thickness and its material constitution.

Advantages of treatment

- Does not change the aspect of substrates

- Long lasting protection against rising damp

- Lets the walls breathe. Water vapor can evacuate from the treated walls.

- CO2 and SO2 can be diffused which limits corrosion of metallic parts as well as sulphate attacks on concrete.

- Sanitizes walls and living areas whilst drying them

- Improves heat insulation

- Reduces moisture spots in rooms

- Good resistance to alkalis

- Good penetration into mineral materials

Product data

Typical general characteristics:

– Translucent liquid light yellow

– Flammable

– Flash point 39°C [ 102°F]

– Neutral pH

– Density at 20°C 0.80 +/-0.3 g/cm3

Application

- Ready to use . Do not mix with other products.

- Do not add water

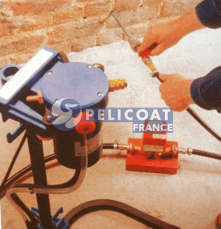

- Use a solvent resistant low pressure injection device to apply

- Do not over apply.

1) Remove any wall decoration items like wall paper, renders, plaster or paint in the bottom part of the wall to make the stonework visible.

2) Drill injection orifices of 10 to 12 mm in diameter depending on the size of device used, in the 1st horizontal line of the stonework joint above the floor.

Remove any dust making sure the orifices will be clear

Injection operations (so drilling ones) can be carried out from inside or from outside the building.

Depth of the orifices will be 2/3rd of wall thickness

Orifices must be separated by 10 cm from each other

3) Pour the product into the tank of the low pressure appliance and pressurize it from 2 to 8 kg / cm3.

Insert the injection stick into the orifice aligning the border of the plastic seal with the edge of the masonry. Make sure the seal is properly positioned and the assembly is sealed.

4) Inject PROJET whilst controlling the amount with the meter.

1,5 L to 2 L of the mixture per linear meter must be injected for every 10 cms of the wall width. This quantity must be divided into the 9 orifices per linear meter.

5) Drying time. The damp-proof system will start operating after 72 hours application. Nevertheless, the drying time of the wall could take from 6 up to 18 months depending on materials, on the thickness of the wall, on the amount of moisture inside it and on the atmospheric conditions inside and outside the building.

Precautions for use

- Mandatory consultation of technical and safety documents before use. For professional use only.

- Flammable liquid and vapors

- Do not smoke while using the mixture.

- Keep away from heat, hot surfaces, sparks, open flames and other ignition sources

- Ready to use product. Do not mix with other products. Do not add water

- Avoid contact with skin and eyes.

- Wash immediately and abundantly with clear water in case of contact.

- Protection gear must be worn by users. Wear protective gloves/protective clothing/ face protection/ eye protection

- Do not ingest. May be fatal if swallowed and enters airways.

- Use in a ventilated space or wear respiratory protection

- Do not pour the product into rivers or streams.

- Stock in a fresh, ventilated space, and not in direct sunlight.

ASK FOR A QUOTE